Nozzle Type Non Slam Check Valve Products FCA Valves

Operating under an ISO 9001:2015 quality management system, all nozzle check valves supplied are unparalleled in quality, performance and longevity. To purchase a nozzle check valve, or to learn more about the complete range of nozzle check valves available at MGA Controls, get in touch today on 01704 779324 or email us at [email protected].

Brass Nozzle Valve

This paper reviews the most common type of check valves: swing, dual plate and nozzle. The pros and cons of each choice will be explained in this review, which can be used as a basis for making the most suitable check valve selection for installation after rotating equipment such as pumps and compressors. Dual plate check valves are compared to nozzle check valves in terms of pressure drop and.

VLV Anvil Spray Nozzle Pack Weed Killer & Herbicide Spray Greentech

The Noreva Nozzle Check Valve designs use no soft parts. Also as there are no wearing parts, it is maintenance free. The springs are sized according to the flow rates to ensure that the valves are in the fully open position during normal use. This minimises cycling of the spring, giving the valves a long design life without regular maintenance.

Dixon 1 in. Polypropylene 45° Single Union Nozzle Valve John M. Ellsworth Co. Inc.

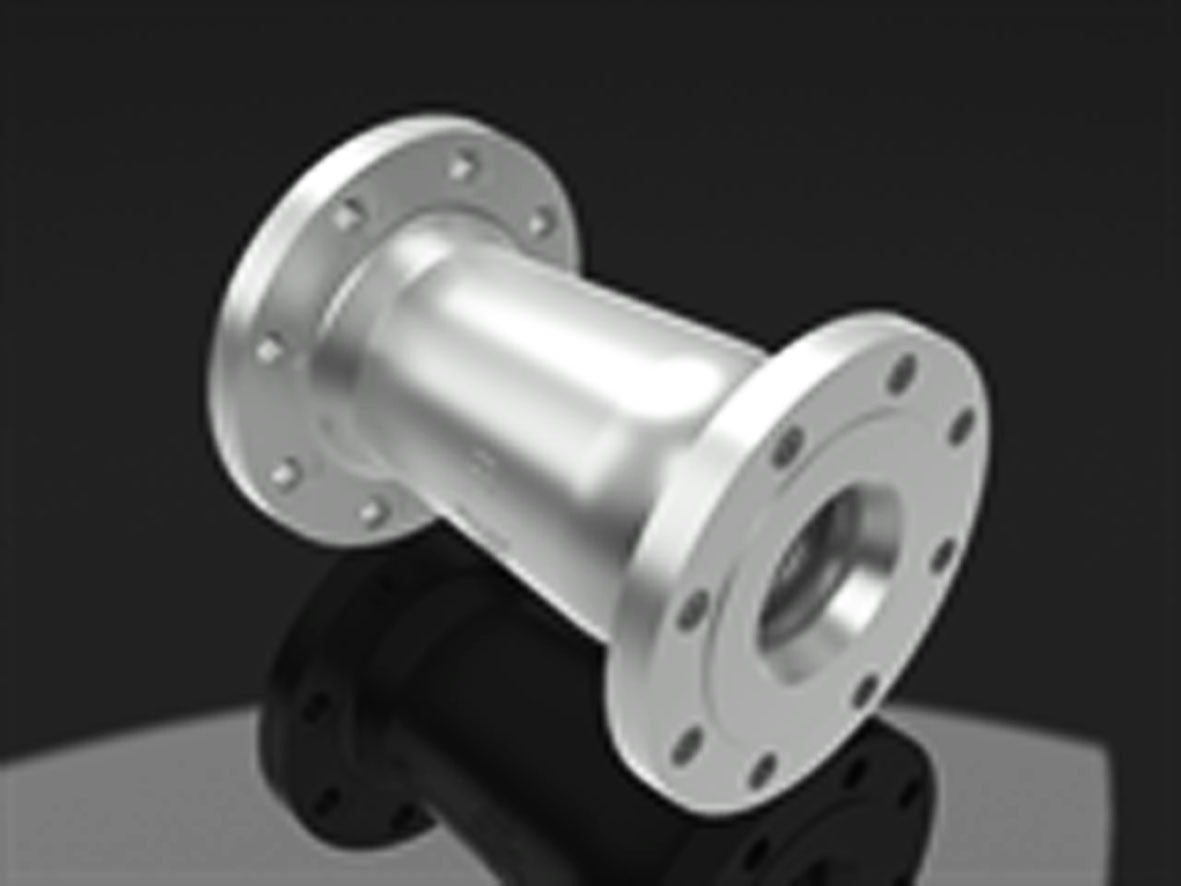

Data sheet. Velan ABV's API 6D Axial No-slam check valves are silent in-line and specifically designed to automatically protect critical components from reverse flow as well as pressure transients. Fast and prompt closing is assured due to the powerful spring and short valve stroke. As forward velocity begins to slow, the spring assist starts.

RN BRASS NOZZLE VALVE, NICKEL PLATED ART NO 1400G&1450G_10MM(3/8") COMBO PACK OF 2 Ball

VarioSpray nozzle valve systems use flexible timing of the spray duration to optimize minimal flow rates - without the need for an expensive and complex twin-fluid system. Benefits across the board. Flexibility thanks to modular system design. Easily adaptable to individual requirements;

CurtissWright Nuclear Nozzle Check Valves InLine Check Valves for Nuclear Plant Applications

Soft seat — All nozzle check valves from DFT ® feature soft seat, a specially designed and sourced O-ring installed in the seat of the valve. Soft seat drastically reduces reverse flow leakage and aids the quiet closing of the valve. Single spring — DFT ® nozzle check valves use only one spring designed for a million cycle life time in.

Nozzle Check Valve VALVE DOMAIN

8" Nozzle Check Valve with Butt-Weld End Valves made of special alloyed steel are offered for high temperature max. 593°C. High Temperature If requested, valve can be supplied with Butt-Weld ends according to ASME B16.25. Optional End Connection Type Important Notice If you receive this catalog as attachment of Vastas offer, please note that,

Jual Nozzle Tembak Pompa Hama Solo VLV 100 atau VLV 200 di Lapak Sinar Diesel Bukalapak

NOZ-CHEK® - High Performance Nozzle-Type Non-Slam Check Valve Crane ChemPharma & Energy www.cranecpe.com. 2 Crane ChemPharma & Energy www.cranecpe.com OPENING Reduced pressure, generated by. NOZ-CHEK® Cryogenic valve can meet the rigorous requirements of BS 6364 (300CC/MIN at -196°C/ -320°F), Shell 77/200, MSS SP-134, ISO 28921-1.

Nozzle Type Non Slam Check Valve Products FCA Valves

Discuss a Project Grayloc® Non-Slam Nozzle Check Valves Delivering superior performance and reliability in a maintenance-free design. Watch the Video Read the Brochure Our Non-Slam Nozzle Check Valve includes an optimized flow profile and unique dual-spring design to solve operational issues, including pressure loss and reverse flow, common with alternative check valve designs.

Jual Nozzle Sprayer Solo VLV 50 Kuningan Shopee Indonesia

Check Valves. The NozzleCheck is a non-slam check valve first developed in 1935. The first NozzleCheck valve installed in a nuclear power plant was in 1972; since then it has replaced over 800 conventional check valve designs.Specifically designed to combat damaging transients and water hammering, the NozzleCheck valve has been improving.

Nozzle Check Valve FG Valvole

Nozzle valves in precision molded polypropylene which is reinforced with fiberglass for additional strength, standard and full port, 1 to 2 inches, stainless steel bolts, lightweight hose end valve for convenient transfer of liquids into drums, tanks etc., angled end flange with 8 inch long polypropylene fill spout.

1" NPSH AL BALL VLV NOZZLE SINGLE GALLONAGE, 95 GPM Specialties Company of Freeport

The nozzle check valve is shown in Fig. 1 and the in-line valve on Fig. 2. Fig. 1. Nozzle check valve. The piping system (Fig. 3) used in the one-dimensional model should be as close as possible to the real valve testing circuit . However, due to the character of the circuit, its model is in principle universal.

Ozkan Nozzle Check Valve Hygrade Water New Zealand

The all-new Delavan ProTek® Nozzle System provides the first step into the future of Clean Air Technology®. This unique, patented System from Delavan provides significant reductions in combustion pollutants for cleaner air. The ProTek Nozzle System includes a factory-installed, one-piece Valve Component which reduces smoke and oil smell in.

Nozzle Check Valves Trillium Flow Technologies™

High PerformanceType 441, 442 Full nozzle DIN. Full lift safety valve with Nozzle , DIN flange connections. Technical data. Delivery times: 2 weeks for standard configurations. Carbon steel and stainless steel casting. Contact LESER Download section.

Brass Straight Nozzle Valve ( S Type ), Brass Inlet Valve, पीतल वाल्व T. G. Brass Industries

Nozzle check valves by Red Point ® can be deployed in a wide variety of applications in the oil & gas and petrochemical industries when high quality, reliable valves are required. A few example applications include: High-temperature services; High-pressure oxygen, nitrogen, or hydrogen; Solids handling (powders, fines, dust, and catalysts)

Nozzle Valve at Rs 40/piece Rajkot ID 10663936348

NOZZLE ChECk VaLVE aDVaNtagEs Energy saving Typically, systems are operated at low flow rates to minimise pressure losses and maximise plant efficiencies. To help operators achieve this, Noreva nozzle check valves can be fully open at a flow velocity of 1.5m/s, ensuring minimal pressure drop across the valve. Non-slamming