Rolls of Fun Photography Cotton Ginning Process

Ginning rate is the primary factor affecting electricity use per bale at a given gin (Hardin IV and Funk, 2012), and has a significant effect on fuel use per bale (Hardin IV and Funk, 2014). The average ginning rate depends on both the actual ginning rate and the frequency and duration of downtime. Increasing the average ginning rate

Fibre to Fabric Ginning & Weaving Science Online Classes Class 6 Swiflearn Session 2

Ginning cotton has come a long way since Eli Whitney's original hand-cranked cotton gin was invented in 1793. Today, gins are mechanically operated and can p.

What is ginning?why it is important Brainly.in

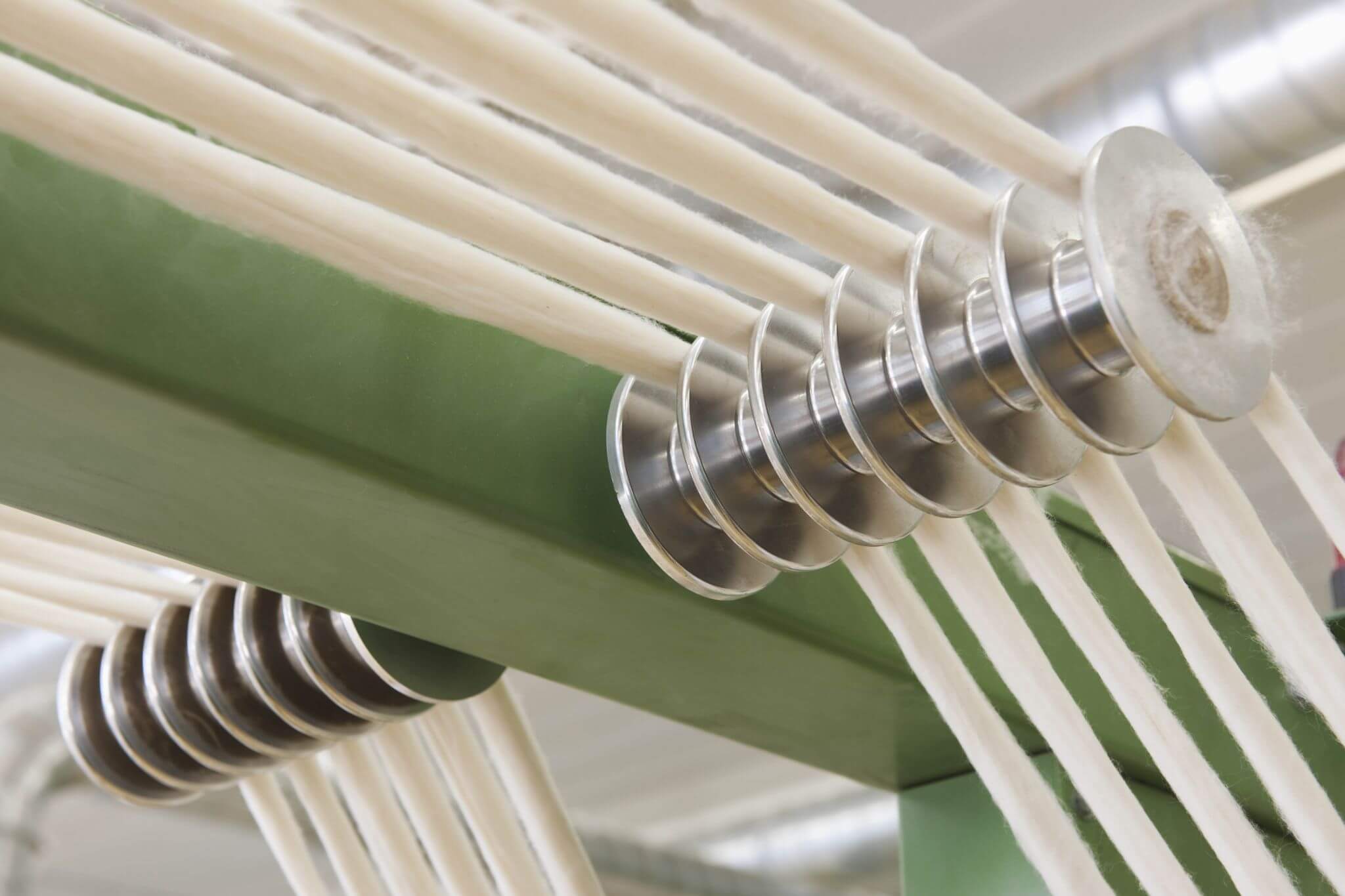

Ginning is a multi-stage process that consists of: The drying, cleaning and dusting of the seed cotton, The actual ginning process and; The cleaning of the lint cotton. After the pre-ginning treatment, seed cotton is ready for seed extraction. The cotton gin separates seeds and removes the "trash" (dirt, stems and leaves) from the fiber.

What is ginning definition of ginning? YouTube

The original ginning process used a simple manually operated device that took hand-harvested seed cotton and separated the cotton fiber from the cottonseed so that the fiber could then be manually spun into yarn and woven into cloth. Today's modern cotton gin has evolved into a complex mechanical system that takes in mechanically harvested seed.

Ginning video3 YouTube

Published in 2020. Development of the Cotton Gin. S. Hughs G. Holt C. B. Armijo Derek P. Whitelock T. Valco. Figure 2. Eli Whitney's cotton gin (taken from Saw and Toothed Cotton Ginning Developments by Charles A. Bennett). - "Development of the Cotton Gin".

How to Start Cotton Ginning and Spinning Mill Business

Pengertian Ginning Adalah. Ginning adalah proses pengolahan serat kapas mentah menjadi serat kapas siap pakai untuk produksi tekstil. Proses ini melibatkan beberapa tahapan, mulai dari pembersihan serat kapas hingga pemisahan serat kapas dengan biji kapas. Tahap pertama dalam proses ginning adalah pembersihan serat kapas.

The Ginning Process YouTube

Ginning outturn (GOT) is a vital component for fiber yield as it is directly associated with lint and it should be analysed with care for fiber quality improvement. It has been reported that yield can be boosted 3% with 1% rise in ginning outturn (Saleem et al. 2010). Fiber length, fiber strength, fiber fineness, fiber elongation and other traits

Ginning video2 YouTube

This educational video describes the Cotton Ginning process, starting with cotton first arriving at the cotton gin to a finished bale that is sent to a text.

The Evolution of the U.S. Ginning Industry Cotton Grower

Ginning. From the field, seed cotton moves to nearby gins for separation of lint and seed. The cotton first goes through dryers to reduce moisture content and then through cleaning equipment to remove foreign matter. These operations facilitate processing and improve fiber quality.

Cotton Ginning Goes Bigger, Better, Faster Cotton Grower

The answer is ginning. Ginning is the process of separating the cotton fibers from the seeds and other impurities, making it ready for spinning and weaving. Ginning is a crucial step in the cotton industry, as it directly affects the quality and value of the final product. It is said that without ginning, the cotton industry wouldn't exist in.

Robin Denim The fabric called denim Ginning & Spinning

National Cotton Ginners Association. Originally established in 1937 with its charter of incorporation in Mississippi, National Cotton Ginners Association is the umbrella organization for eight state and regional ginner associations. National Cotton Ginners Association also represents approximately 500 individual cotton ginning operations in 17.

Ginning Cotton Ginning, Process, Types, and Objectives ORDNUR

Risus sardonicus. A classical sign of Tetanus, risus sardonicus is a form of facial dystonia producing a fixed smiling or grinning expression. Risus sardonicus or rictus grin is a highly characteristic, abnormal, sustained spasm of the facial muscles that appears to produce grinning. It may be caused by tetanus, [1] [2] strychnine poisoning, or.

D'source Hand Ginning Making Process D'Source Digital Online Learning Environment for Design

Here we will discuss Ginning, Cotton Ginning, Process, Types, and Objectives. It is one of the most important steps of the spinning process. After collecting seed cotton from the field, cotton moves to nearby gins for separation of lint, seed and any other foreign particles. The production of a typical gin is about 12 bale per hour (here 1 bale.

Brazil's 2020/21 cotton crop enters ginning season Cotton Brazil

Roller ginning began with the Churka gin, which was developed during the 12 th and 14 th centuries in India and China. This gin produced 5 pounds of lint per day. Nowadays, a 40-inch wide high-speed roller gin stand processes cotton at 1,900 pounds of lint per hour, and is used to gin Pima and high-quality Upland cottons grown in the Western U.S.

Madame Tay ALL ABOUT COTTON PART I Tracing the Seeds of Fabric

An experimental ginning roller covering, made from woven fiberglass, was tested on a roller gin stand to evaluate its ginning performance and effect on fiber quality. The experimental covering was.

Karunanand Fully Automatic Cotton Ginning And Pressing Plant, 150 To 300 Hp, Rs 32500000 /set

Published: June 1, 1995. Cotton Ginning. To attract settlers to his colony in Spanish Texas, empresario Stephen F. Austin advertised the richness of the lands along the Brazos and Colorado rivers as suitable for growing cotton as a cash crop. Jared Ellison Groce, one of the first colonists, moved to Texas from Alabama in January 1822 and bought.