01.13 Zinc Chromate Primer 31 Protective Paints

The chromate reacts with the zinc, forming a protective and complex film on the surface. The resulting zinc chromate coating offers improved resistance against corrosion in diverse environmental conditions. Additionally, it facilitates strong adhesion for subsequent coatings, such as primers or paints, contributing to the overall durability of.

Cat Dasar Kuda Terbang Zinchromate

They rely on the direct reaction of Cr3+ with the dissolved 492 Table L Average Film Composition of Hexavalent Yellow Chromate Conversion Coating Composition % by wt Cr6+ 8.7 Cr3+ 28.2 S (as sulfate) 3.27 Zna+ 2.12 Na+ 0.32 Water 19.3 Oxygen Bal. zinc and produce insoluble barrier layers of zinc chromium oxide precipitated on the surface in a.

Pancing Zinc Chromate Alkycoat Paint

We developed a facile method to produce a uniform chromate conversion (CC) coating on zinc alloy-plated steel substrates (ZS). When an acidic CC solution is applied to ZS (C-ZS), zinc is dissolved.

Pinnacle Zinc Chromate Primer Yellow Super Globe, Inc.

These results suggest that zinc chromate is a more potent human carcinogen when inhaled than other chromate pigments such as lead chromate. In the study by Hayes et al. (1989), much lower RRs were reported despite higher air concentrations than recorded the study by Langård and Vigander (1983).

Zinc Chromate Primer PDF Paint Chemistry

Notes. Go To: Top Data from NIST Standard Reference Database 69: NIST Chemistry WebBook The National Institute of Standards and Technology (NIST) uses its best efforts to deliver a high quality copy of the Database and to verify that the data contained therein have been selected on the basis of sound scientific judgment.

Zinc chromate basic hydrate, 99 (pure) chemcraft.su

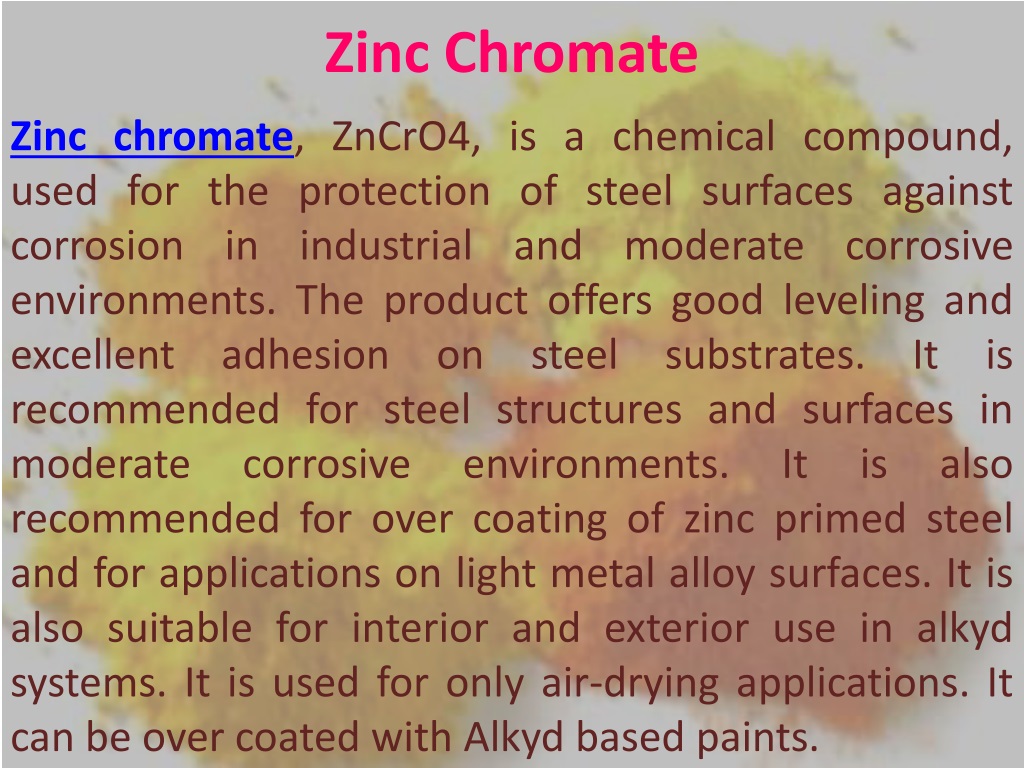

Zinc chromate is used for a wide range of applications. It is an odorless chemical compound primarily used as an industrial paint coating. The compound is a beneficial coating because it is an anti-corrosive and an anti-rust primer. It is primarily used to coat aluminum and iron materials. Developed by the Ford Motor Company during the 1920s.

NAA53065 13530659 Zinc chromate Biosynth

zinc alloy by forming the chromate coating. The black chromate conversion coating on zinc alloys can achieve a corrosion protection of 250 - 350 h to first appearance of white rust in the NSS test. This result is comparable to the corrosion protection of yellow or olive chromate coatings of the same layer thickness. Crack formation is.

Zinc Chromate Coating lupon.gov.ph

SUMMARY The search for low toxicity alternatives to Chromate for the formation of conversion coatings (passivation treatments) for zinc-based surfaces, has been a long one. For many years no real candidate was found to be completely suitable, a variety of possibilities being examined. More recently trivalent chromium-based treatments have been suggested as possibly the answer.

Zinc Chromate Primer Protective Nippon Paint Meni Besi 1Kilo 1Liter Lazada Indonesia

Physical and Chemical Properties. Zinc Chromate presents as a yellow crystalline solid at room temperature. It is odorless and does not dissolve easily in water. It exhibits strong oxidizing properties and reacts with reducing agents. Its molar mass is 181.38 g/mol, and it possesses a density of 3.43 g/cm 3.

Zinc chromate, Thermo Scientific Chemicals Fisher Scientific

Other articles where zinc chromate is discussed: chromium processing: Pigments: Zinc yellow, a basic zinc chromate, is used as a corrosion-inhibiting primer on aircraft parts fabricated from aluminum or magnesium. Molybdate orange is a combination of lead chromate with molybdenum salts. Chrome green is a mixture of lead chromate with iron blue. This pigment has excellent covering and hiding…

Zinc chromate Sciencemadness Wiki

Structure, properties, spectra, suppliers and links for: Zinc chromate, 13530-65-9, 15748-91-1.

PPT Zinc Chromate Potassium DiChromate Sodium Chromate PowerPoint Presentation ID1507604

Accu-Labs 560 is a two-part liquid concentrate which, when diluted with water, will produce a glossy, jet-black hexavalent chromate conversion coating on all types of zinc plated parts. Accu-Labs 560 coatings give superior corrosion protection up to 96 hours of salt spray to white rust per ASTM B 117.

Zinc Chromate Warna Agung

This suggests that the chromate in the coating has a cathodic inhibitive effect in the corrosion of zinc. PS analysis of the chromate conversion coatings (at.%) Summary of fitting to Cr 2p 3/2.

zinc chromate Esaar International Pvt. Ltd.

Immersion chromate coatings are applied to zinc deposits to increase further the corrosion resistance of the zinc electrodeposits.1,2 The chromate layers are deposited from either hexavalent or trivalent solution, and the coatings are mixtures of hydrated hexavalent and trivalent chromium compounds. Various degrees of corrosion protection are.

Jual Zinc Chromate PT. Gochem Globalindo

The main visual difference is the bright red color of the red oxide as compared to the yellow-green color of the zinc chromate. But the main difference is the increased effectiveness of the rust preventative qualities found in zinc chromate as compared to red oxide. If you are shopping for a rust-preventative in your primer, you may run across.

Fungsi Zinc dan Perannya bagi Kesehatan Tubuh Jovee.id

Zinc chromate, which has the chemical formula ZnCrO4, is a chemical compound used to protect metals from corrosion.It was developed by the Ford Motor Company in the late 1920s as a primer coating. By 1936, it was used by the aviation industry and the U.S. military. While this coating is still in use, due to health risks and skin irritation, less toxic substances and other organic compounds are.