S36 Rock Drill BOART LONGYEAR [Ground Construction Underground

The adoption of intelligent drilling technologies represents a critical step towards more efficient, safe and sustainable underground mining operations, though eco-efficient rock processing.

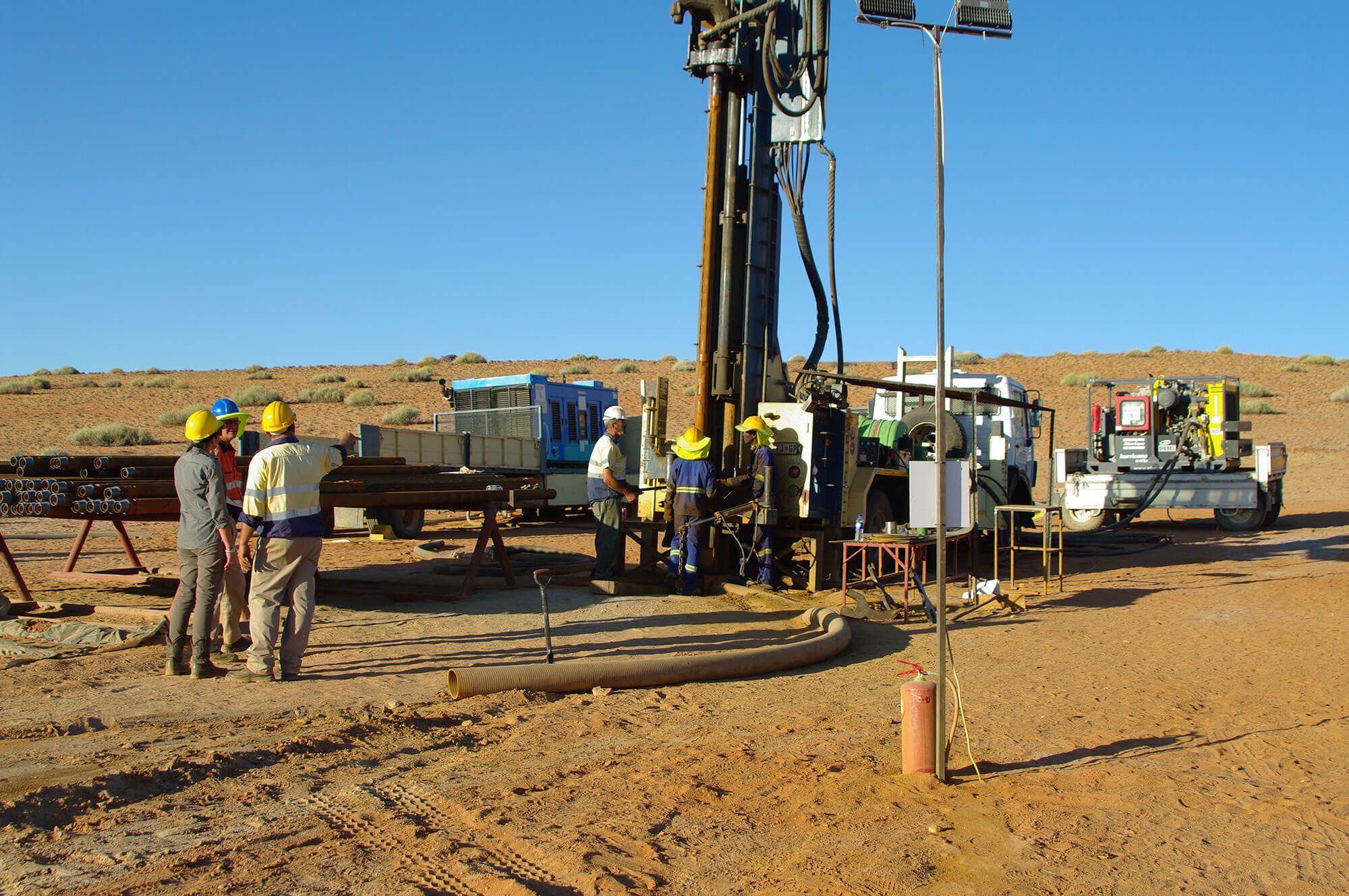

Capital Drilling growing fast throughout Africa International Mining

The mining business is in great need of new drilling solutions that meet the challenges of mining deeper, bigger and narrower - and at the same time protecting the environment and reducing the costs. Many existing underground mines are reaching extreme depths that current mining methods cannot manage cost efficiently.

Drill and Blast Don’t discredit the Drill MEC Mining

Drilling and blasting are the two most significant operations in open pit mines that play a crucial role in downstream stages.

Types of Drilling in Mining CR Mining

Drilling and blasting. Drilling and blasting is the controlled use of explosives and other methods, such as gas pressure blasting pyrotechnics, to break rock for excavation. It is practiced most often in mining, quarrying and civil engineering such as dam, tunnel or road construction. The result of rock blasting is often known as a rock cut .

DRILLING Epiroc introduces DM30 II SP blasthole drill Canadian

Drilling is used to obtain detailed information on rock types, mineral content, rock structure, and the relationship between rock layers near the surface and at depth. They are used in areas selected on the basis of geological, geophysical and/or geochemical methods. The different drilling techniques

Epiroc to showcase surface drilling automation expertise at CONEXPO

Over the past few decades, drilling technology has rapidly evolved, with several innovative solutions emerging in recent years to address key challenges in the mining industry. This article will explore some of the current rig innovations and techniques driving the industry forward in the 21 st century. Automated Drilling Rigs

Blast Hole Driller D65 2/1 Roster Perth WA iMINCO Mining

It is a technique used in the mineral mining sector to (1) explore for new mineral prospects (2) evaluate land for economic mining (3) augment additional ore reserves and resources in the mine. Exploration drilling enables discovery and acquisition of new mineral deposits amenable to economic extractive operations now or in future.

Sandvik expands batteryelectric range with new top hammer longhole

Abstract. The process of utilising drill and blast techniques is used to improve mining performance. Drill and blast techniques have been proven to be more efficient and cost-effective compared to conventional mechanical rock breakage with machines. The degree of efficiency of the drill and blast process varies from mine to mine.

EQUIPMENT Epiroc launches new mobile underground drilling rig

Drilling operations are widely used in mining and numerous other engineering operations. Drilling operations are crucial for opening holes in the ground (blastholes, injections, boreholes, diamond wire holes in natural stone mines, groundwork constructions), during the development and production activities of underground and open-pit mines together with the construction of dams, tunnels, roads.

Sandvik introduces automation ready DR410i rotary blasthole drill

What is diamond drilling in mining? Diamond drilling is the act of drilling boreholes using bits inset with diamonds as rock-cutting tools. It is a drilling method for exploration purposes. Cylindrical rock cores from the rock mass are removed with the help of a hollow bit covered with diamonds. Invented by a French engineer named Rodolphe.

Mining Exploration Drilling Mincon The Driller's Choice

Types of Drilling in Mining Drills have different mining functions, from providing geologists with different samples of soil for analysis to facilitating the extraction of precious minerals that would otherwise be difficult to reach. How many methods of drilling are there?

Licensing and permitting ensuring a successful diamond core drilling

It is an operation of drilling holes in the stope of an open pit for separating and crushing original ecological ore rocks by blasting method. It is the first process of surface mining, and the quality of the drilling has a great influence on the subsequent blasting, mining, etc. During the whole process of surface mining, the cost of drilling.

Exploration diamond drilling Wikipedia

We provide innovative mining equipment, consumables and services for drilling and rock excavation. Whether the application is surface and underground mining, infrastructure, civil works, well drilling or geotechnical, Mining and Rock Excavation Technique will ensure to increase customers' productivity.

Sandvik's fully automated & digitised DL432i leads its newly upgraded

The types are: 1. Percussive Drilling 2. Rotary Drilling. Method # 1. Percussive Drilling: In this method which is the oldest one of drilling, the hole is drilled by striking a number at short in intervals on the rock by a chisel-type tool and between the blows the tool is rotated slightly.

Drilling Techniques for Mining Exploration Equipment & Contracting

Drill Tech Drilling & Shoring, Inc. was founded in 1994 by Shannon Creson and Dave Shupe. Thanks to their ingenuity, determination and years of hard work, what began as a home-grown two-man operation, has become a nationwide business. Drill Tech specializes in earth retention, foundation support, mining, tunneling, shaft construction, ground.

Drilling machine in open cast mining quarry Stock Photo Alamy

Drilling & blasting is the most essential part of the mining industry that plays a crucial Ore Recovery = Extracted Ore Extracted Ore + Unextracted Ore × 100 role in downstream stages.