Die Cut Stickers vs Kiss Cut What's the Difference? (And a GIVEAWAY) Silhouette School

While creating kisscut sticker sheets, the outside of the sticker design is cut by a plotter or a sharp metal die, and it bites through the sticker and only "kisses" the paper. The words "kissing the paper" is an easy way to remember the way a kiss cut sticker is cut. Kisscut sticker sheets are gentler than a die cut sticker process.

Know the difference between diecut stickers & kisscut stickers

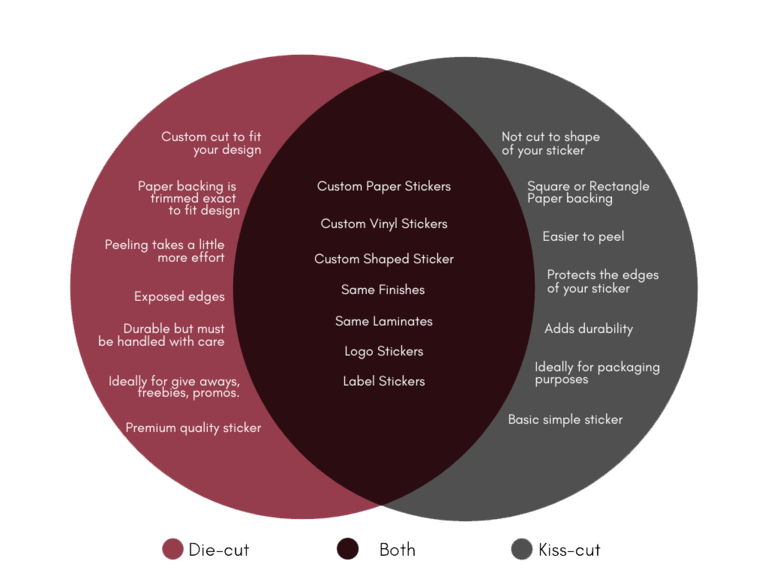

The cutting technique impacts the sticker shape, edges, and usage. Die cut stickers have crisp edges perfect for logos. Kiss cut stickers lend themselves to custom shapes and photos. This post breaks down the pros, cons and ideal uses for kiss cut vs die cut to help choose the best method for your stickers business. We'll also cover tips for.

How to Kiss Cut and Die Cut Stickers on Same Sticker Sheet Silhouette School

Convenience: Kiss-cut stickers come on either rolls or sheets. They're great for adding to packaging or products. They're also great for creating sticker packs, and they're easy to store in stacks on sheets or hanging on rolls. Versatility: While not as intricate as die-cut stickers, kiss-cut stickers can still be printed in a variety of.

DieCut vs. KissCut Stickers Which You Should Use To Promote Your Business

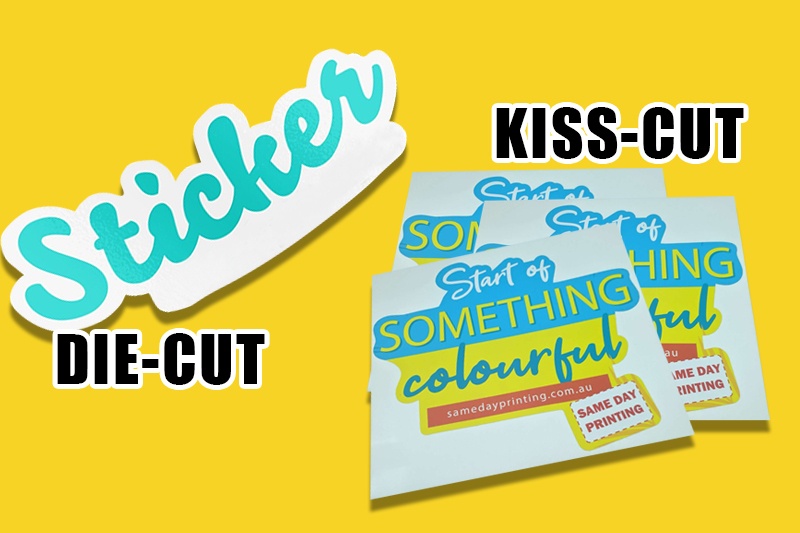

The difference between die cuts and kiss cuts is the depth of the cut. A die cut will cut all the way through a material leaving just the desired shape. A kiss cut is a shallower cut that cuts the first layer of material into the desired shape but leaves the material backing untouched. Die cutting and kiss cutting each has its own very specific.

KissCut vs DieCut The Ultimate Sticker Guide

Stickers have become an integral part of personal expression, branding, and marketing in today's visually-driven world. When it comes to choosing the right type of stickers for your needs, two popular options stand out: die-cut and kiss-cut stickers. In this blog post, we will review the characteristics, uses, and benefits of each type, helping you make an informed decision for your first.

Die Cut vs. Kiss Cut What is the Difference? Personal Die Cutting

The main difference between these two popular sticker cut options comes down to the finish of the paper backing. A die cut sticker is cut completely through the sticker and its paper backing. Whereas a kiss cut sticker is only cut through the sticker layer. The paper backing stays intact and will leave you with an extra border for protection.

Kiss Cut vs Die Cut YouTube

Need to apply the stickers immediately, in the printed shape, on a container or packaging. Can neatly apply the edges on the surface. Kiss cut stickers are also cut to the shape of your choice but come with a larger paper backing. Compared to die-cut stickers, kiss-cut pieces are easier to peel off and protects the shape's edges from damage.

DieCut vs. KissCut Stickers Which You Should Use To Promote Your Business

Luckily, the difference between die-cut and kiss-cut stickers isn't complicated: Die-cut stickers are cut through both the sticker vinyl and the paper backing, so that the paper backing of the sticker is the same exact shape as the sticker design. Kiss-cut stickers are cut only through the sticker vinyl, so that the paper backing remains intact.

Kiss Cut Vs Die Cut Stickers — What’s The Difference? Printmoz Blog

The term "kiss cut" refers to the process where the sticker is cut, leaving the backing intact. Kiss cut stickers can be easily peeled off from the backing and applied to various surfaces. The process of creating kiss cut stickers involves using a sharp blade or special machine to cut the sticker material while leaving a thin border, or.

Die Cut Stickers vs Kiss Cut What's the Difference? (And a GIVEAWAY) Silhouette School

A kiss cut is usually produced using a digital die cutting machine since the pressure required to cut only the first layer will be very specific to the material being cut. Kiss cuts are typically used in sticker production as well as creating iron-on designs or vinyl decals. If you think of a sheet of stickers or labels, the kind with multiple.

Kiss Cut vs Die Cut Sticker Ninja

Unlike die cutting, which cuts through both the top layer and the backing of a material, kiss cutting involves the use of a specialized die with sharp blades set to cut through only the top layer while leaving the backing untouched. This intricate process requires careful adjustments to ensure that the blades are set at an appropriate depth.

Perbedaan Stiker Die Cut dan Stiker Kiss Cut Tokopedia Blog

Kiss cut stickers are cut around the edge of your design through the vinyl layer only.Extra backing around your sticker remains, protecting your sticker and.

Diecut vs. Kisscut Sticker Printing Same Day Printing

Die-cut stickers are cut all the way through, creating a custom shape, while kiss-cut stickers are cut only through the sticker vinyl, leaving the paper backing intact. Both types of stickers are made of vinyl and have a backing that will stick to almost anything. Design is an essential aspect of stickers. A logo or a unique shape can make a.

Diecut vs. Kisscut Sticker Printing Same Day Printing

A kiss-cut sticker is a type of custom sticker that's cut to a specific shape, leaving a paper backing that holds the design in place. Unlike die-cut stickers, which are cut all the way through the backing material, kiss-cut stickers are only cut through the vinyl layer. This means that the paper backing stays intact, making it easier to peel.

Die Cut vs Kiss Cut YouTube

Kiss cutting, also known as pressure sensitive cutting, is a type of die cutting where the blade does not penetrate the entire stack of material, but rather cuts through a precise number of layers. The application of kiss cuts occurs when the sharp edge or blade punctures the surface layer(s) of a material but stops at the top of another one .

Die cut vs. Kiss cut stickers YouTube

Kiss-cut stickers have extra backing paper, useful for brand promotions or additional information. Die-cut stickers don't have extra material to utilize for branding. Surface types. Ideal for smooth surfaces such as glass, plastic, and paper. Suitable for uneven and textured surfaces like bikes or water bottles.