Vapour Blasting Services Sydney Mobile Abrasive Blasting

Vapor blasting (also known as wet blasting, liquid honing, or dustless blasting) is a process that uses pressurized water and abrasive material to remove contaminants, corrosion, residue or coatings from a surface. The vapor blasting process provides the highest quality soft surface finish. It is commonly used for cleaning aerospace parts and.

Vapor Blasting Vapor Honing — City Garage Motorcycle Shop

Wet blasting (vapor blasting) is a process for removing contaminants from a surface, or finishing a surface using pressurized water and abrasive blast media. If the abrasive media is mixed with water and pressurized in a pressure pot before being propelled through a blast nozzle and mixed with compressed air. This process is generally known as.

Graco EcoQuip 2 Vapor Blast EQ Dual Graco Mexico

Dikembangkan oleh Inggris pada perang dunia kedua untuk menciptakan tegangan permukaan beberapa bagian pada turbin jet tempur mereka. Vapor Blasting dapat digunakan untuk benda logam seperti kepala silinder, karburator, kotak engkol, hub roda, tong, braket, penutup samping, baut, silinder utama, kaliper, rotor, dan masih banyak lagi.

JRA Vapor Honing/Blasting services Wet Blasting, Media Blasting

https://vaporhoningtechnologies.com/buying-a-vapor-blaster-how-much-does-it-cost/Vapor Blasting describes the process of mixing water and abrasive together a.

Vapor Blasting 101

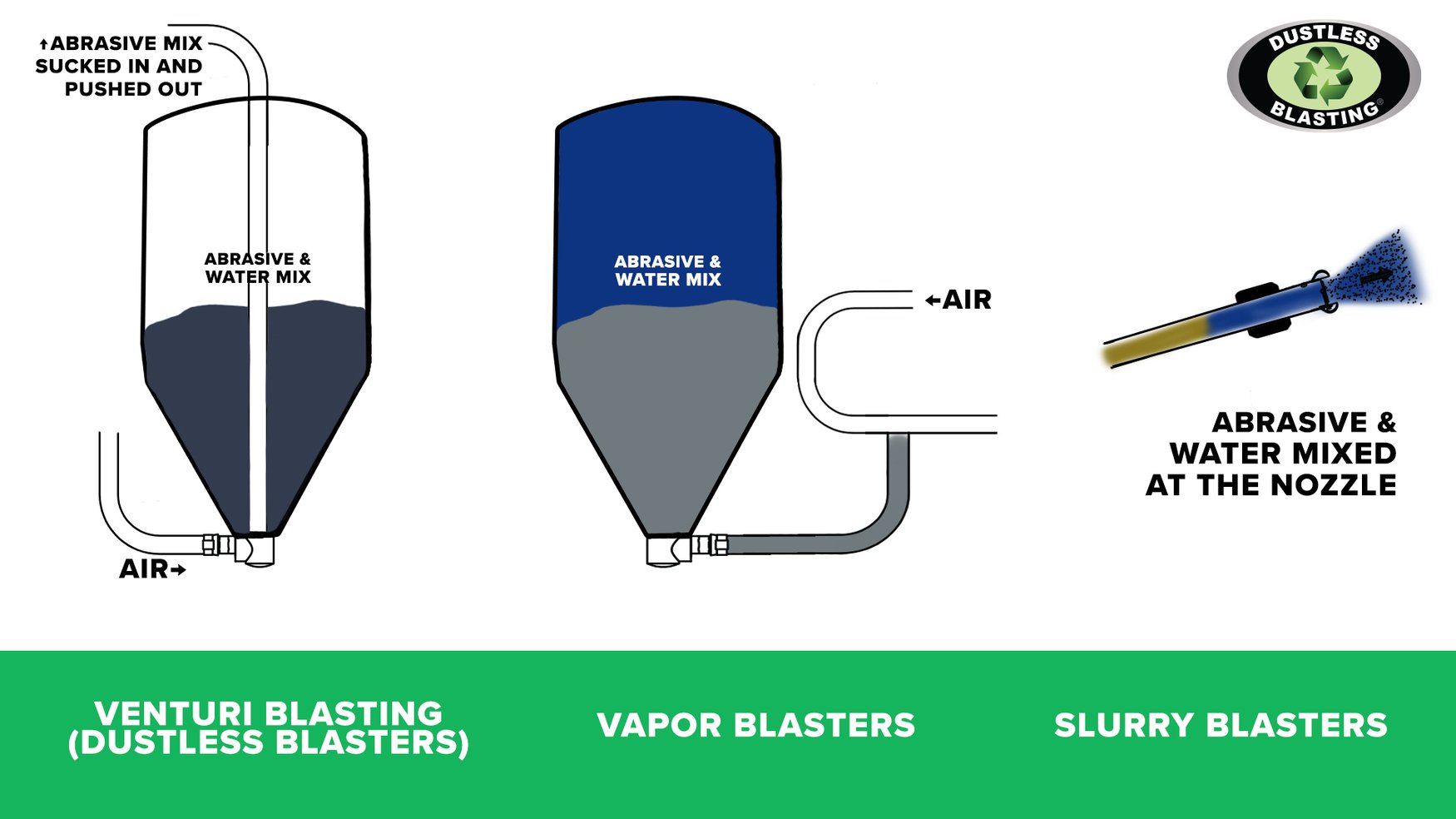

Vapor blasting or vapor honing are two phrases used interchangeably to describe the vapor blasting process. Like other wet blasting technologies, a vapor blasting machine starts with a mixture of water and abrasive in the blast pot chamber. From there, the mixture is forced out of the chamber and to the nozzle by air pressure within the pot.

What is Vapor Blasting? Vapor Honing Technologies

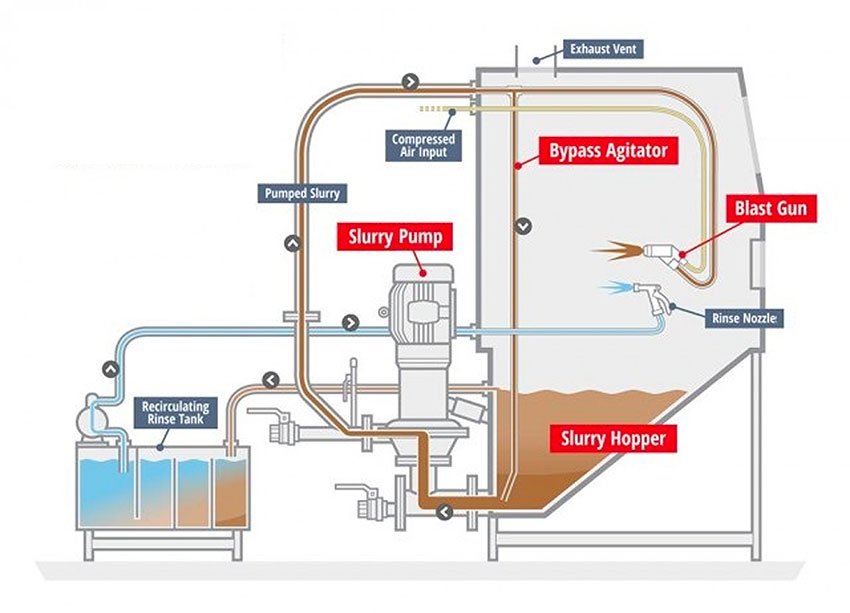

This slurry is mixed into a fluid and evenly mixed as a liquid in the bottom of the hopper. We normally refer this as the sump. The liquid is pumped up to the blasting gun and compressed air accelerate the mixture propelling it towards the part. Depending on the vapor blasting application air pressures can range from 20 PSI- 150PSI but 70-80.

Mengenal Lebih Dalam Cara Kerja Vapor Blasting

Sand Blasting Uses. Sand blasting has many of the same uses as vapor blasting. You can safely use it to prepare and finish surfaces in the engineering, agricultural, industrial, and aerospace industries. The main difference is the harsher blasting of sand makes it a better option for harder and more durable materials.

IMG_2492aa Vapor Blasting Equipment for Sale Vapor Honing Technologies

Vapor blasting is a form of abrasive blasting that uses water mixed with an abrasive media such as glass beads, aluminum oxide, or crushed glass to clean and prepare surfaces. It is also known as wet blasting. Unlike traditional sandblasting that just uses compressed air, vapor blasting reduces dust with the addition of water and allows for.

powder coating solo Mengenal jenis vapor blasting powder coating solo

Vapor Blasting - EVERYTHING You Need to Know 🔥 How To Media Blast - Tips Tricks Tools & TechniquesToday, I want to show you guys my entire vapor blasting se.

Vapor Blast Video Demonstration YouTube

Beda dengan dry blasting yang mengandalkan tekanan atau tembakan gas dari kepala nozzle, wet blasting/vapor blasting bekerja dengan konsep aliran cairan dengan tekanan sedang. Sebab itulah vapor Blasting, yang juga dikenal sebagai proses W et Blasting atau Liquid Honing ini banyak dipilih untuk permukaan benda-benda atau bangunan yang memiliki.

powder coating solo Mengenal jenis vapor blasting powder coating solo

The Cabinet. Our vapor blasting equipment is self-contained. To clean and restore parts and components, you insert them into the box or the cabinet. When blasting, the cabinet is sealed shut, containing the blasting process, dust, moisture, and residue. The biggest variable when choosing a vapor blasting machine is the type and size of your.

Vapor Blasting 101

Optimal Paint Adhesion. The success of any paint job relies heavily on proper adhesion. Vapor blasting creates a surface that promotes excellent paint adhesion. By removing impurities and creating a clean, porous surface, our vapor blasting technique ensures that the paint bonds securely to the surface, resulting in a smooth, durable finish.

PROCESS Vapour Blasting

Vapor blasting, also known as wet blasting or vapor honing, is a surface preparation process that involves the use of an abrasive media combined with water to remove coatings from a variety of surfaces quickly and safely with pressurized air.Choosing the right abrasive media is crucial to the success of the vapor blasting process. In this blog post, we will explore the best abrasive media to.

Vapor Blasting 101

In this video I present you the DYI vapor blaster I built. I bought a regular sand blasting cabinet and converted it to a vapor blaster to clean engine part.

Vapor Blasting Application Photo Gallery Vapor Blasting Equipment for Sale Vapor Honing

6. The Cathedral of Nuestra Senora de Los Remedios. It is a roman catholic church, completed in 1915, dedicated to the Virgin of Los Remedios which is the patron of the Roman Catholic Diocese of San Cristóbal de La Laguna and the island of Tenerife. 7. Square of the Supreme Council of the Canaries.

Vapor Hone 1000 Wet Blasting Equipment Blast & Wash Systems

This involves blasting water and compressed air against a surface in order to clean it. It is also known as wet blasting, vapor honing, and dustless blasting. You can use vapor blasting to remove almost anything from surfaces such as stone, metal, or concrete. For example, you could use it to clean a car or to remove dirt from a garden patio.