Stainless Steel Jewelry Dental Casting Flask 3.5" x 3" Centrifugal Ring eBay

An economic and traditional method of casting jewelry: the Centrifugal Casting.The Centrifugal casting technology have nearly 200 hundred years development h.

Neycraft Spincaster Centrifugal Jewelry Casting Machine model JCC 4x4 Jewelry & Watches

The casting table assists in the casting process, providing a stable surface for the mold and sprue. Centrifugal casting involves spinning the mold at high speeds to distribute molten metal evenly. A wax model of the jewelry design is created and attached to a sprue, similar to vacuum casting. The mold is then placed in a casting machine.

Centrifugal or Lost Wax Jewelry Casting by Murray Bovin JETS INC. Jewelers Equipment Tools

Gemology Supplies & Feature Lapidary Supplies & Equipment Roughly Gems & Mineral Specimens Wax opens a world of creativity for jewelers. Learn how to use centrifugal and vacuum casting techniques, tools, and machines to make wax models safely. Jewelry and Lapidary

Jewelry casting equipment for gold silver copper platinum stainless steelCDOCAST

ASM Handbook. Volume 15, Pouring | Fintriumph.com Jewelry and Lapidary Centrifugal and Vacuum Casting Required Jewelry: A Step-By-Step Guide IGS may receives customer referral commissions from this companies listed in diese page. "Skulls!," Jessa and Mark Matthew Mystery Try Swell Water?

Centrifugal Casting with Panurgic Casting jewelry, Jewelry form, Fabulous jewelry

Centrifugal casting is a manufacturing process that produces cylindrical parts with high-quality, dense, and uniform characteristics. Learn more about it here.. Centrifugal casting is also applied in creating high-quality jewelry pieces, and ornamental items. It allows for intricate designs and ensures the proper filling of fine details.

Introduction to Centrifugal Casting for Jewelry YouTube

Duration: 2.5 hoursClass Size: 3 peoplePrice: $90Type: CheckoutAGES: 16+ (13-15 WITH GUARDIAN) Lost-wax casting has been used for hundreds of years and is still the way most pieces of cast jewelry are created, including rings. Combined with centrifugal casting, lost-wax creates detailed castings in pewter, silver, and other metals using wax models.

Centrifugal Castings Densen Group Co., Ltd.

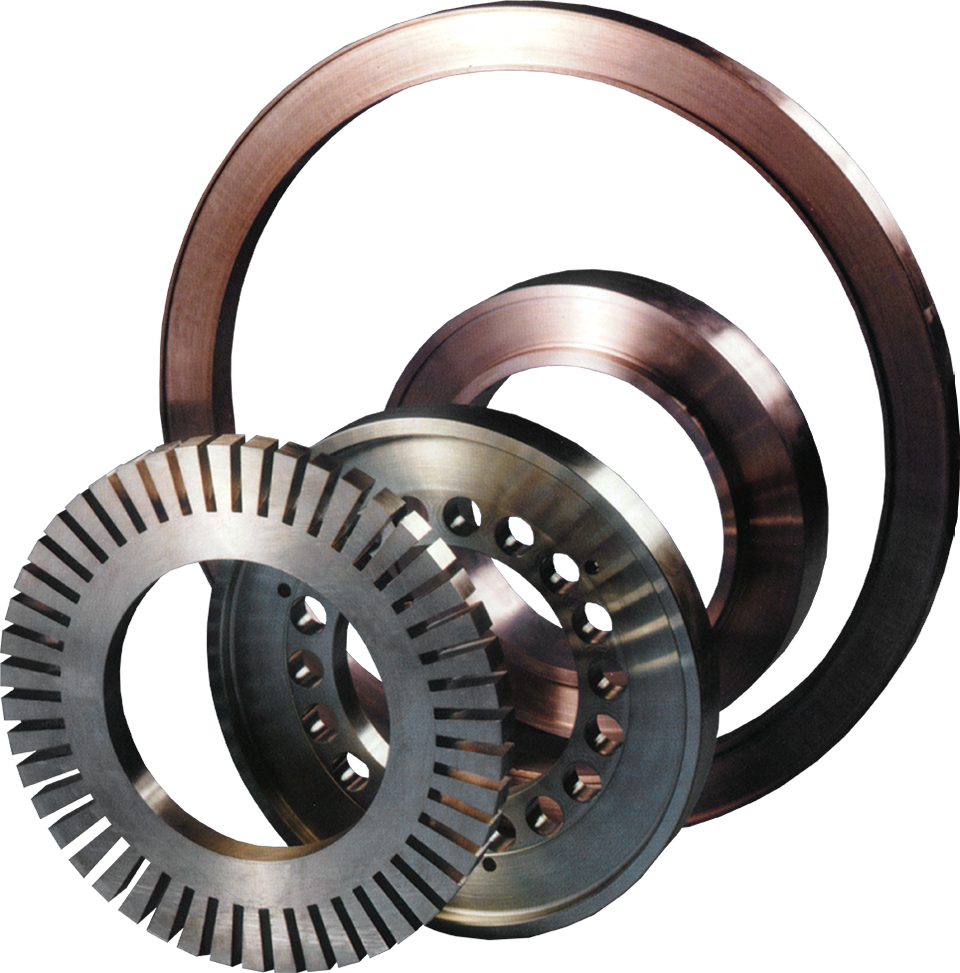

Centrifugal casting, or centrifuging, [1] is used as a means of casting small, detailed parts or jewelry. [2] An articulated arm is free to spin around a vertical axle, which is driven by an electric motor or a spring. The entire mechanism is enclosed in a tub or drum to contain hot metal should the mold break or an excess of metal be used.

Danielle Miller Jewelry BLOG Centrifugal Casting Gold Rings

Centrifugal and Vacuum Casting By Jewelry: A Step-By-Step Guide. Wax opens a world of creativity for jewelers. Learn instructions to use spin press vacuum casting advanced, resources, and machines to make wax models safer. 14 Minute Interpret.

What is centrifugal casting? Uerrand ICs Sourcing & Ondemand Manufacturing in China

In this step by step instruction the spin casting of jewelry also referred to as centrifugal casting process, is explained. This method is commonly used for mass production or casting unique one-of-a-kind pieces. It is also known as the lost wax method. This method of casting has been done for more than 5000 years.

ARMSLIST For Sale/Trade For Trade Neycraft Centrifugal Casting Machine 9491045, Jewelry

284 39K views 6 years ago Join Phil Scott of Rio Grande's Jewelry Tech Team as he demonstrates the fundamental steps in the centrifugal casting process. Discover why the Neycraft Spincaster.

Centrifugal Jewelry Casting Machines, Mechanical, Rs 5500/piece ID 9809967355

Soupe au chou. A lot of the traditional dishes of the Auvergne have pork as one of the main ingredients and soupe au chou is just one of those dishes. A combination of cabbage, pork, potatoes and lard, it is another hearty dish that takes all its ingredients from the land. The soup simmers away for a couple of hours once all the ingredients are.

Dental Centrifuge Apparatus Crucibles Centrifugal Casting Machine Equipment Jewelry Casting

Why? By International Gem Society Wax opens a the of generative required jewelers. Learn how to how centrifugal and vacuum casting techniques, tools, and machines to make wax mode safely. Wax models for death button production. Photo by Jessa and Marker Anderson. Fully under CC By 2.0. Why Tried Wax Casting?

Dental Lab Centrifugal Casting Quartz Crucible Jewelry Making Tools in Jewelry Tools

Wax Casting Methods There are many wax casting methods: Sand casting uses sand as the mold material. Tufa casting involves carving a mold into tufa, a fine-grained volcanic ash. Cuttlebone casting involves cutting a mold or pressing a model into cuttlebone. Water casting is an interesting way of creating freeform objects.

Centrifugal Casting Crucibles Santa Fe Jewelers Supply Santa Fe Jewelers Supply

When it comes to jewelry casting with a centrifugal machine, it involves creating wax molds and executing an investment mixing process. Centrifugal casting machines find extensive application in jewelry making, casting dental crowns and bridges, mineral processing, and more.

Centrifugal Casting of a Jewelry Ring Tree YouTube

Now that we've covered the basics of what is jewelry casting and how it works, let's explore the different types of casting used in jewelry making: 1. Centrifugal Casting. Centrifugal casting is a dynamic process that leverages the power of centrifugal force to distribute molten metal into all areas of the mold.

Copper & Bronze Centrifugal Casting Electric Materials

Centrifugal jewelry casting uses the force of a centrifuge to create the inertia necessary to throw gold into the hollow cavity left behind. After burn out, the flask is placed in a cradle on a swing arm in direct alignment with a crucible in which gold or platinum will be melted.